Cement Slurry 3D Printer

Everplast has developed advanced cement 3D printing machines, including EM3-3505-CMT and EM3-6020-CMT. EM3-3505-CMT: Equipped with a professionally designed extrusion screw, this machine is suitable for printing with cement, cement mixtures, and other slurry materials. EM3-6020-CMT: A large-scale 3D printer featuring an automatic feeding and raw material mixing system, capable of printing large objects up to 8 cubic meters, providing strong support for large-scale manufacturing applications.

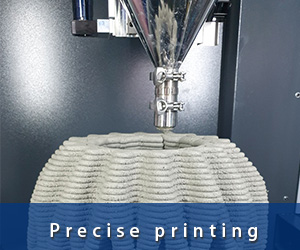

EM3-3505-CMT

The specially designed extrusion screw allows for printing with a wide range of materials, such as cement, cement-like mixtures, and more.

A standard formulation database and material library are provided with the 3D printer.

Printing Range: 500 x 500 x 500 mm

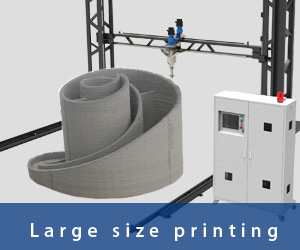

EM3-6020-CMT

Maximum printable area: 4 square meters.

Equipped with an automatic feeding system and a raw material mixing system.

Specifically designed for printing large objects, this 3D printer ensures high-efficiency large-scale manufacturing.

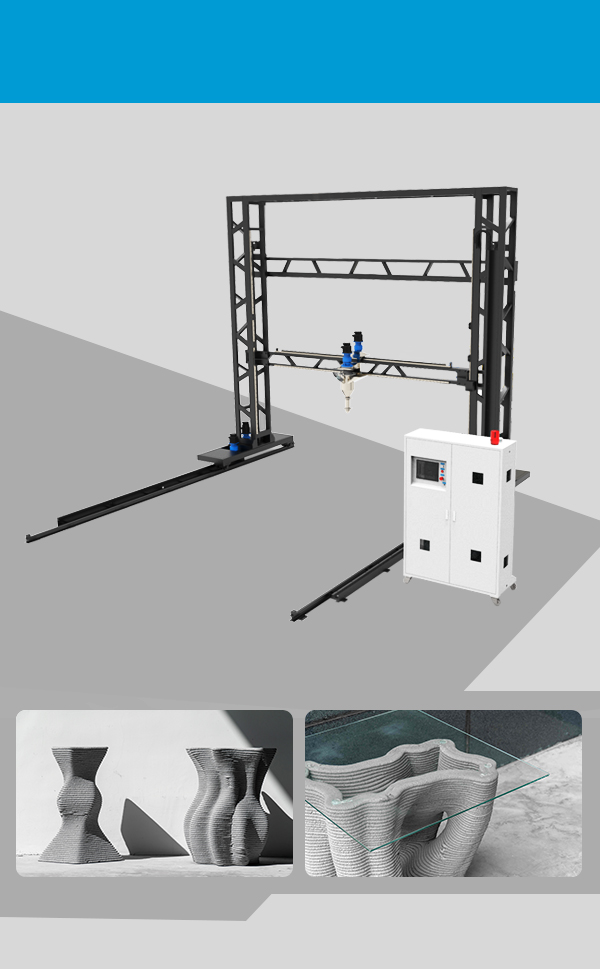

EM3-6030-CMT

Equipped with an automatic feeding system and a raw material mixing system. This 3D printer is specifically designed for printing large objects.

Printing range: 3000 x 3000 x 3000 mm.

The cement extrusion 3D printer enables a wide range of applications, from artistic creations to large-scale architectural landscapes. This equipment supports various print sizes, making it ideal for small-scale art installations, outdoor public installations, furniture partitions, floral designs, as well as large-scale architectural components and landscape structures.

With the ability to process various composite materials, it realizes innovative design concepts while optimizing manufacturing workflows through cement 3D printing technology. From artistic beauty to functional structural construction, this machine helps designers and construction teams explore new possibilities, providing a powerful solution for the future of architecture and living spaces.

Materials

Composite Materials

Cement Slurry

The cement slurry 3D printing machine offers high material compatibility, supporting various composite materials for printing. Common materials include cement and slurry, with the option to incorporate recycled slag powder, oyster shell powder, and other sustainable materials, blended with river sand and other components to achieve both environmental sustainability and innovative applications.

To ensure optimal printing quality, all material formulations undergo strict testing and validation to meet different production scales and design requirements.

Features

Automated mechanical printing significantly reduces human error, ensuring high accuracy and stability in the printing process. Offers extreme design flexibility, accommodating customized and complex geometries. Seamless file conversion into printing codes simplifies operation, enabling fast and efficient execution of creative designs.

Supports large-format printing, catering to a variety of creative demands—from small intricate art pieces to outdoor landscape installations and even full-scale architectural structures. Printing range reaches 300 x 300 x 300 cm, providing a stable and efficient solution for large-scale creations, breaking size limitations and enabling boundless design possibilities.

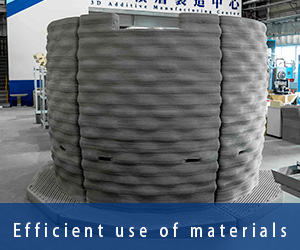

No need for traditional formwork, eliminating the cost and labor associated with conventional construction templates. Prints only the required structure, maximizing material efficiency, reducing waste, and enhancing cost-effectiveness. Supports green manufacturing and sustainable development.

Exceptional material compatibility, allowing versatile composite material printing. Supports a wide range of cement-based and alternative materials, including recycled slag powder and oyster shell powder, fulfilling diverse industrial and creative applications.