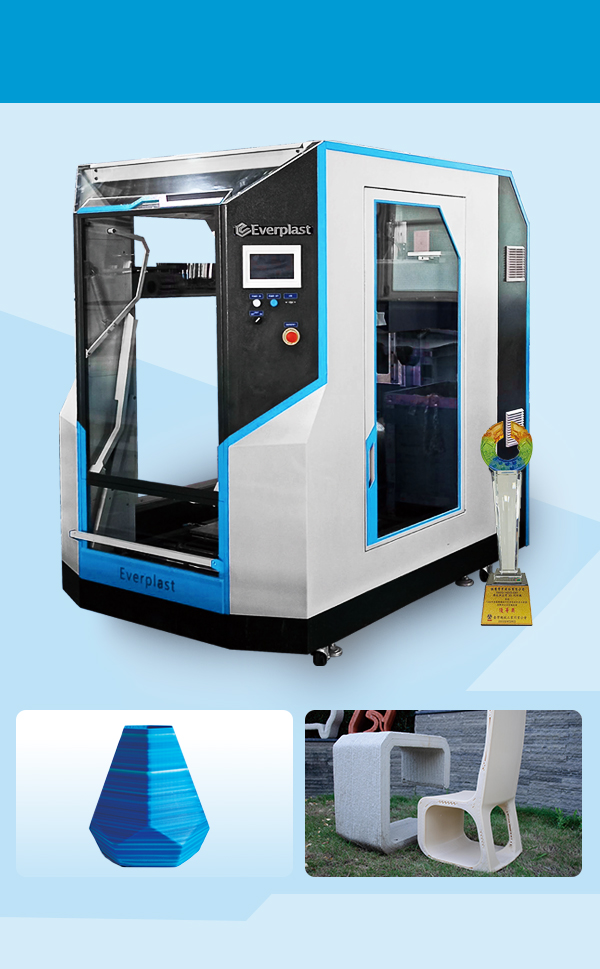

Pellet 3D Printer

Everplast’s Pellet 3D Printer utilizes advanced plastic pellet extrusion technology, using plastic pellets as printing material. Compared to traditional filament-based 3D printers, the Pellet 3D Printer can increase printing speed by up to 70%, significantly reducing print time while offering greater material flexibility to accommodate a wide range of applications.

EM3-1005-D

Equipped with intelligent upgrade functions, making operation more convenient, including auto shutdown, preheating, pause, resume printing, and automatic material drying. The servo-driven system and PID+SSR precision temperature control system not only save energy but also ensure high-precision printing results.

Printing size: 500 x 500 x 500 mm

EM3-1505-D

High-temperature Pellet Extrusion 3D Printer, equipped with chamber temperature control and heated bed functionality.

Supports external cooling water circulation for enhanced thermal management.

Printing size: 500 x 500 x 500 mm

EM3-2510-T

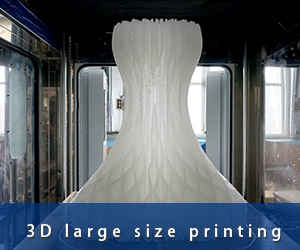

Our ultimate goal is to develop and manufacture various pellet extrusion 3D printers to meet all the diverse requirements of our customers. At the same time, we will collect and enrich the molding database to assist our customers in a wide range of applications. Compared to traditional FDM 3D printers, our faster printing speed allows us to save 30% to 70% of printing time. Printing size: 1000 x 1000 x 1000 mm

EM3-2520-C

The EM3D-25-20-C is an industrial pellet 3D printer manufactured by Everplast in Taiwan. This 3D printer can utilize composite plastic materials to produce products or prototypes. A standard formulation database and material library are provided along with the 3D printer.

Printing size: 2000 x 800 x 600 mm

The Pellet 3D Printer supports various printing scales, making it suitable for:

- Small-scale character models

- Interior furniture design

- Functional partition walls

- Floral design elements

- Indoor public art installations

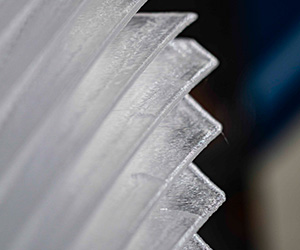

Designed to handle complex geometries with ease, the Pellet 3D Printer delivers high-precision prints, ensuring superior product quality to meet customer demands.

Materials

Available Materials Hard Materials Soft Materials Special Blended Materials

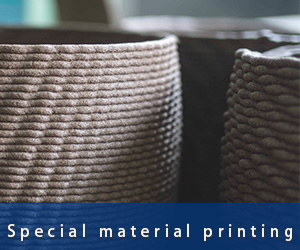

The Pellet 3D Printer supports a wide variety of materials, including:

- Soft materials: EVA, TPU

- Hard materials: ABS, PC, PA, HDPE

- Special blends: PC+ABS, PA+Fiber, WPC (Wood-Plastic Composite)

Features

Significantly reduces production time, ensuring fast turnaround. 3x faster than conventional filament-based 3D printers, making it ideal for rapid prototyping and pre-production runs.

Supports both soft and hard plastic materials, meeting various manufacturing needs. Compatible with EVA, TPU (soft materials), ABS, PC, PA, HDPE (hard materials), and advanced material blends.

Maximum printing size: 200 × 80 × 60 cm. Ideal for large indoor furniture, including tables, chairs, and interior décor. Can print large planters, partition walls, and other large-scale interior installations.

Supports advanced composite materials such as PC+ABS, PA+Fiber, and WPC, offering stable and efficient production performance.