Machine Advantages

1. Innovation

2. Functionality

- Core controller monitors equipment operation

- Supports production parameter storage

- Simplifies material switching for seamless operation.

Features

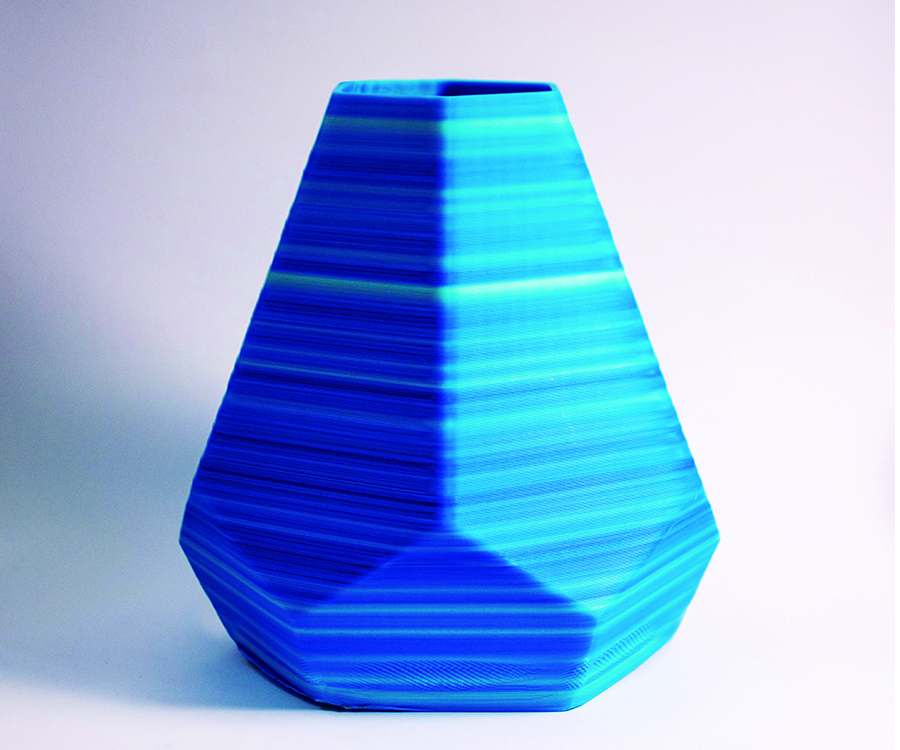

3. Aesthetic Design

4. Sustainability

- Expanding to high-temperature materials such as PEEK, PI, and PPS

- Broadening application fields and market scalability.

5. Market Potential

- Targets industrial clients

- Focuses on specialty plastics and large-format printing, offering high growth potential.

- One-stop solution including materials, equipment, and contract printing services, meeting diverse customer demands.

3D Printing Applications

1️⃣ Functional Prototypes

✔ Product prototype testing: Rapidly produces functional prototypes for high-temperature and impact-resistant applications.

✔ Mold & casting models: Ideal for rapid mold and master model fabrication, reducing traditional manufacturing time.

2️⃣ Specialty Plastic Products

✔ High-performance materials: Supports PEEK, PPS, PI, suitable for high-temperature and chemically resistant applications.

✔ Custom material applications: Allows direct pellet printing for materials unavailable as filaments, expanding material options.

3️⃣ Large-Scale & Artistic Installations

✔ Architecture & Interior Design: Creates large-scale decorative elements, artistic installations, and architectural models.

✔ Public Facilities & Landscape Applications: Suitable for benches, planters, sculptures, and other outdoor structures.