Machine Advantages

🏆 Winner of the 2022 TaipeiPlas Award – Excellence Prize

✔ Recognized as the only award-winning plastic extrusion 3D printer in its category

✔ Features intelligent operation, aesthetic design, eco-friendly energy efficiency, and high precision

✔ Helps customers reduce three major cost factors, balancing practicality and market potential

1. Direct Pellet Usage

✔ Uses plastic pellets instead of traditional filament, optimizing the unique material feeding system.

2. Enhanced Printing Speed

✔ Addresses the time-consuming nature of traditional additive manufacturing, significantly improving printing efficiency.

3. Advanced Fused Deposition Modeling (FDM) Technology

✔ Pellet-based material application expands beyond conventional FDM limitations, broadening the range of usable materials.

4. Sustainable & Eco-Friendly

✔ Supports recycled crushed materials as fillers, reducing environmental pollution and achieving sustainability goals.

5. Multi-Functional & Precision Engineering

✔ XYZ three-axis structure provides a compact yet efficient machine design, enhancing operational accuracy.

Features

✔ Faster Printing Speed – Patented nozzle structure significantly boosts efficiency.

✔ Diverse Material Compatibility – Supports various plastic materials to meet different application needs.

✔ Broad Industry Applications – Ideal for automotive parts, castings, specialized models, prosthetic aids, and large figurines.

✔ Soft Material Support – Prints soft foam materials, making it applicable for custom footwear production.

✔ High Market Demand – Popular in industries requiring specialized materials and functional applications.

3D Printing Applications

E-Plast’s Pellet Extrusion 3D Printer: Redefining the Future of Additive Manufacturing

E-Plast’s pellet extrusion 3D printer is revolutionizing the possibilities of additive manufacturing with its innovative granular feeding system, high-performance printing capabilities, and versatile applications. From industrial production to artistic design, from medical applications to sustainable manufacturing, this technology continues to expand the boundaries of additive manufacturing, unlocking new opportunities for the future.

As more industries adopt and integrate this cutting-edge solution, E-Plast’s 3D printing technology will remain at the forefront of innovation, driving global manufacturing toward greater intelligence, efficiency, and sustainability.

1️⃣ Industrial Component Manufacturing

✔ Cost-effective material use – Uses plastic pellets directly, lowering raw material costs compared to filament-based FDM.

✔ Flexible plastic compatibility – Supports ABS, PP, PE, and other plastic types.

✔ Ideal for functional prototype production, such as:

- Custom machine gears, connectors, and piping.

- Large-format automotive components, including impact-resistant structures and interior parts.

✔ High-speed printing with strong layer adhesion, comparable to traditional manufacturing.

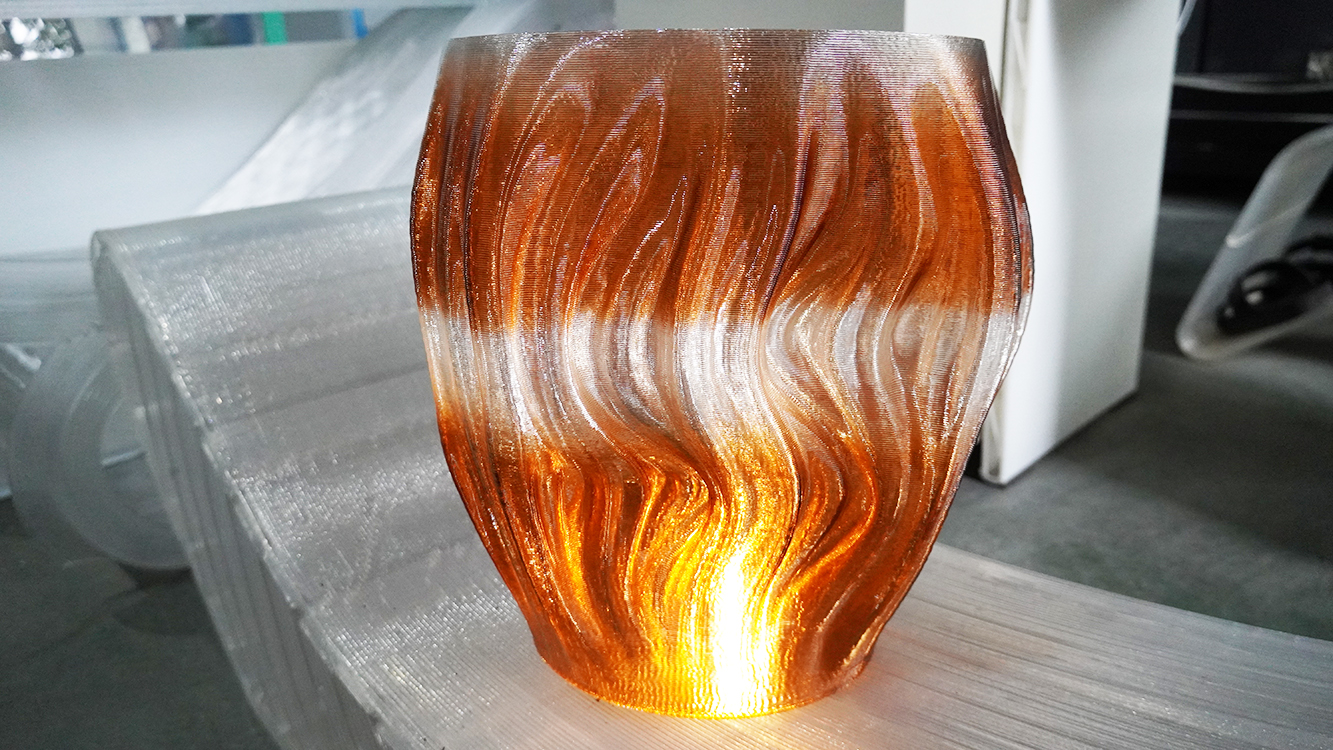

2️⃣ Architectural Models & Art Installations

✔ High-efficiency production for architectural modeling and design prototyping.

✔ Capable of producing intricate geometries for installation art and sculptures.

✔ Supports mixed material printing for unique visual effects and textures.

3️⃣ Medical Equipment & Prosthetics

✔ Used in creating orthotic devices, prosthetic limbs, and custom medical aids.

✔ Enables fast production of patient-specific medical tools, reducing development time.

✔ Supports biodegradable materials for sustainable medical applications.

4️⃣ Environmental & Circular Economy Applications

✔ Integrates recycled plastic pellets, promoting eco-friendly and sustainable manufacturing.

✔ Used in packaging and display applications, transforming industrial waste into new products.

5️⃣ Education & Maker Spaces

✔ Perfect for schools and maker spaces, offering low-cost, high-efficiency prototyping.

✔ User-friendly interface with quick material switching, allowing for easy operation.

6️⃣ Consumer Product Design & Manufacturing

✔ Applicable for footwear, lighting, home décor, and customized consumer goods.

✔ Allows designers to quickly prototype and refine products based on market feedback.