Everplast / E-Plast

History of 3D Printing Technology

Key Milestones in Everplast's Journey of Innovation

Founded with a focus on the development, production, and sales of plastic extrusion machinery and molds for applications such as "pipes, profiles, pellets, and wood-plastic composites."

The first factory is built successively with an area of 3,182.53 square meters.Expanded its facilities to increase production capacity, successfully building a comprehensive service model integrating marketing, R&D, design, manufacturing, and turnkey production lines. Everplast is committed to providing tailor-made solutions for customers worldwide.

Everplast/E-Plast Tainan Factory 2 was gradually constructed and expanded. The second plant was established with an area of 3,389.44 square meters, bringing the total area of Factory 1 and Factory 2 to 6,571.97 square meters. The company now has 50 team members.

Everplast initiated the early development of 3D printing technology, leveraging decades of accumulated extrusion expertise to formally expand into the 3D printing field.

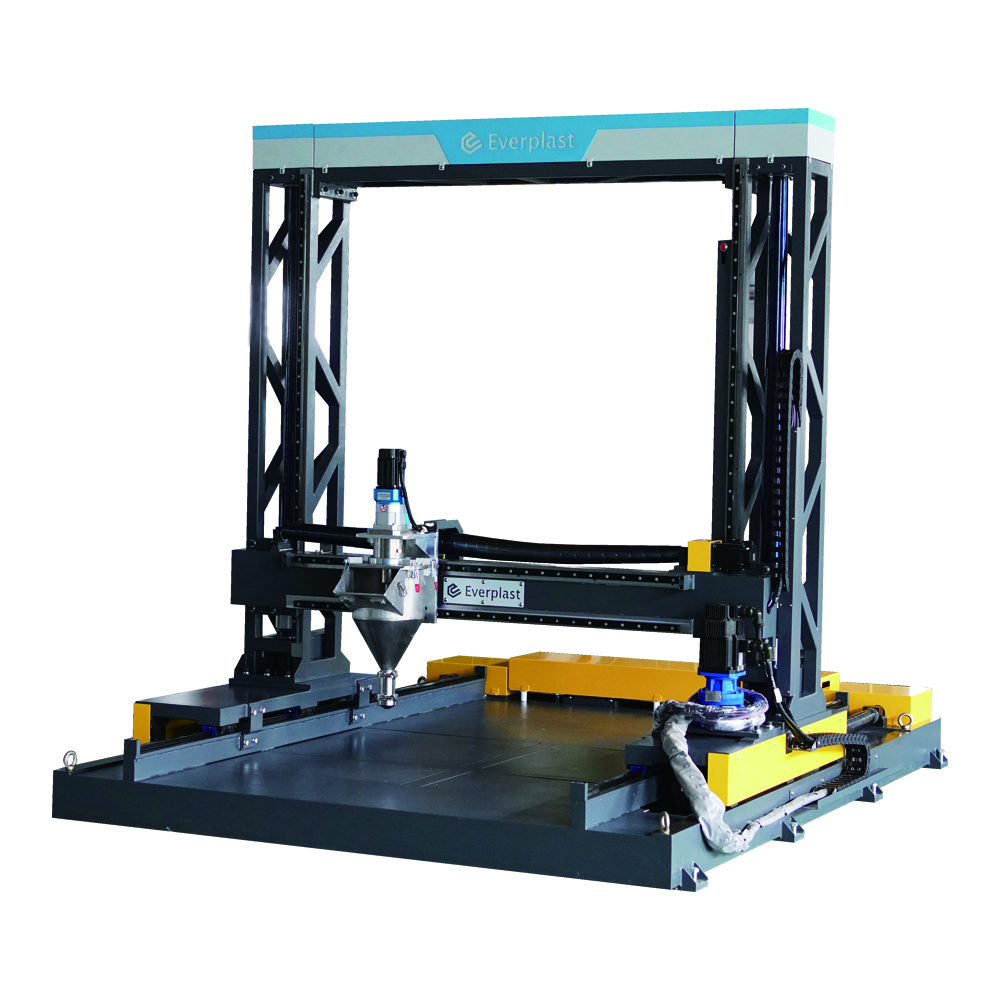

Everplast has demonstrated extraordinary potential and innovative strength in the field of 3D printing, gradually developing a series of 3D printers designed for the future of manufacturing. Our expertise in extrusion technology has successfully extended into 3D printing, enabling a wide range of printing applications.

Printing size: 300 x 300 x 300 mm

The extrusion-based cement 3D printer EM3-3505-CMT was officially launched, marking the beginning of cement 3D printing applications.

Through industry–academia collaboration with National Cheng Kung University (C-Hub) and Lotos, Everplast successfully developed a slurry/cement 3D printing system, advancing innovation in construction materials.

The system supports a printable build volume of 500 × 500 × 500 mm.

Printing size: 1000 x 1000 x 1000 mm

Design of High-Temperature Pellet 3D Printer & New Slurry 3D Printer, expanded application possibilities. Printing size: 2000 x 800 x 600 mm

High-Performance 3D Printing Series

Printing size: 500 x 500 x 500 mm

Winner of the "2024 Taipei Exhibition Gold QualityAward"

Printing size: 500 x 500 x 500 mm

Successfully developed a 1.2-meter cement 3D printer. paving the way for large-scale landscape installations. Printing size: 1200 x 1200 x 1200 mm

Launched the development plan for a 3-meter cement 3D printer, laying the foundation for the realization of large-scale architectural printing technology. Printing size: 3000 x 3000 x 3000 mm

The scale of 3D printing has evolved from 1.2 meters to 3 meters in cement 3D printing, and even further into architectural-scale printing.

With continuous technological innovation and market insight, Everplast is at the forefront of shaping the future of 3D printing technology, committed to providing more efficient and creative solutions for users worldwide.